Safety company Pyroban® has launched a new series of long-life exhaust flame arrestors to maximise ‘zone 2’ powerpack productivity.

“We have developed a simple system that puts a stop to the 8-hour cleaning routine of plate type exhaust flame arrestors in prime movers,” says Rob Double, Sales Director for Pyroban. “Operators can now get on with the job, enjoy longer operation and reduce the non-productive downtime of temporary well service equipment.”

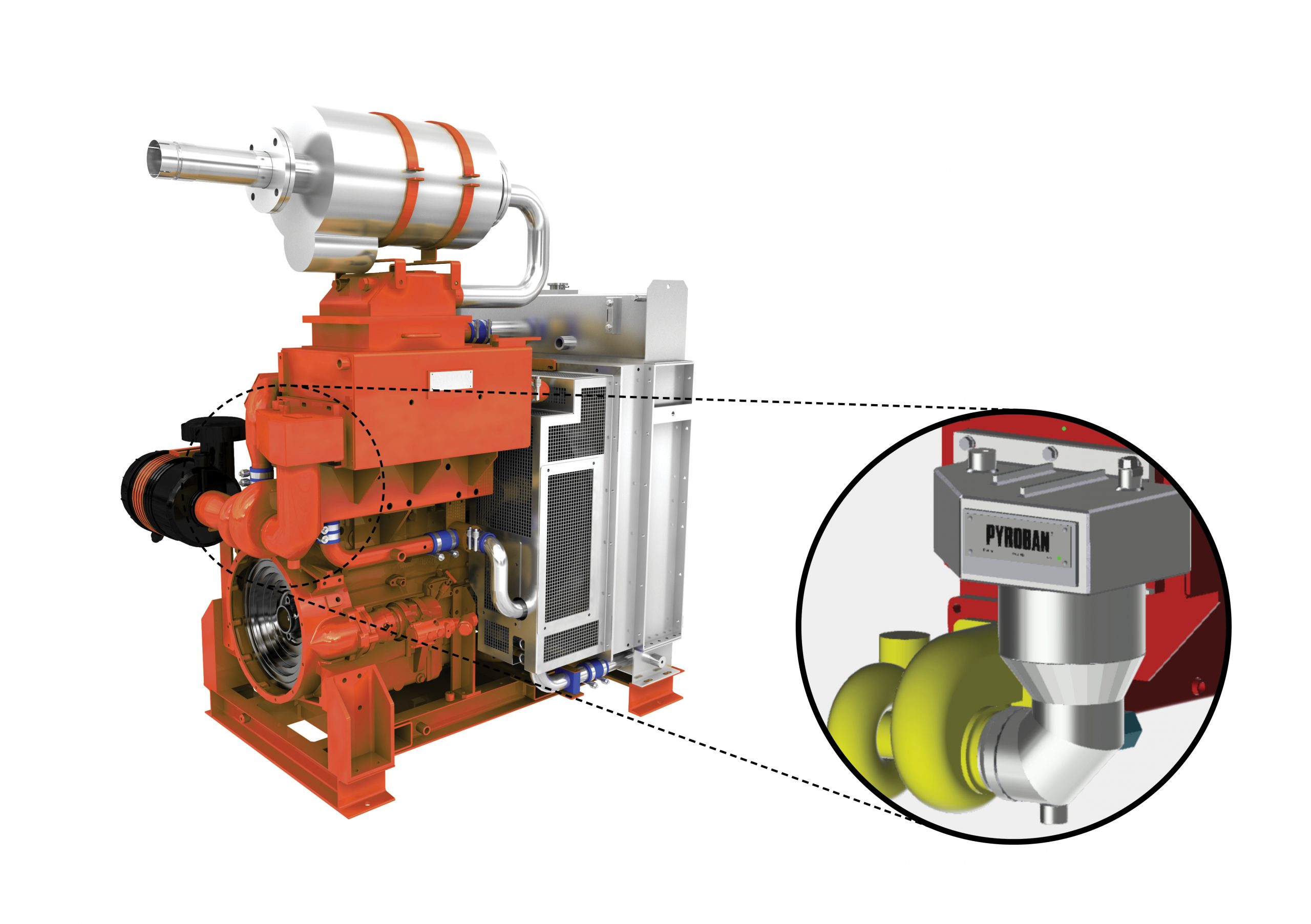

Ever Clear™ Exhaust (ECE) Flame Arrestors are a direct replacement for plate type flame arrestors. Developed by Pyroban, the new long-life flame arrestor is bolted into the exhaust system between the turbo and gas cooler, on the hot side of the exhaust flow.

“For as little as half the annual cleaning costs of a plate type exhaust flame arrestor, operators can upgrade their existing assets with Ever Clear,” he says, explaining that exhaust flame arrestors are a critical part of the ATEX system found on explosion proof diesel engines used in Zone 2 hazardous areas offshore. They allow the engine exhaust gases to pass through but will stop a flame in the event of hydrocarbon gas ingestion.

“Operators can now overcome the safety risks associated with wrongly using a ‘dummy arrestor’,” he says, enforcing that dummies expose the operation to sources of ignition and invalidate the whole Pyroban system.

Manual handling compliance issues also disappear with Ever Clear. The traditional plate type exhaust flame arrestors typically weigh over 25kg and are usually located above waist height making them hard to handle.

“After many years development, Ever Clear is finally here following field trials, extensive testing and the completion of the EN1834-1:2000 non-flame transmission tests,” confirms Rob.

Suitable for new, or existing, Pyroban protected turbo diesel engines above 100bhp the Ever Clear Exhaust Flame Arrestors can operate for up to 1000 hours before cleaning is required, dependent on diesel quality and duty cycle.

The development is the second part of a two-pronged strategy by Pyroban to eliminate plate type exhaust flame arrestors in explosion proof diesel engine design. The first started nearly 20 years ago when Pyroban spearheaded the gas detection route with 3GP™, and more recently ExSCS™. However, Pyroban reports that some customers and territories just wanted a simpler option, particularly for smaller engines fitted to slick line, compressors and generators in Asia Pacific which led to the development of Ever Clear.

Suitable for T3, IIA & IIB gas groups, Ever Clear Exhaust Flame Arrestors are available on Pyroban kits and HazPaks™ and should now form part of the periodic maintenance schedule.

“With our extensive back catalogue of Pyroban designs spanning 50 years over many engine brands, we can engineer the plate type exhaust flame arrestors out of existing equipment and fit Ever Clear in the field,” says Rob.

Find out more at www.pyroban.com, call +44 1273 456825 or email sales@pyroban.com.